Infrastructure

Home / Infrastructure

Machinery

At Pinnacle Clothing, our state-of-the-art Broderie Anglaise infrastructure exemplifies our commitment to intricate craftsmanship. This sophisticated setup blends traditional techniques with modern technology, ensuring each garment embodies timeless elegance and the highest quality. Our dedicated team meticulously oversees every step, delivering exquisite, handcrafted fashion that showcases our dedication to excellence.

At Pinnacle Clothing, our artisans excel in the timeless art of cut work and hand embroidery, offering a diverse range of styles. Skilled in techniques like beadwork, sequins outline work, counted thread work, and void work, they bring each piece to life with exceptional detail and craftsmanship. This blend of traditional expertise and innovative design ensures every creation meets the highest standards of quality and artistry.

Pinnacle Clothing’s multi head computer embroidery service offers precise and intricate designs, enhancing our apparel with a touch of elegance and professionalism. Utilizing state- of-the-art embroidery machines and advanced software, we transform digital artwork into high-quality, consistent stitched patterns. Whether for fashion embellishments, or custom creations, our automated embroidery process ensures each piece meets the highest standards of detail and durability, reflecting the exceptional quality Pinnacle Clothing is known for.

Pinnacle Clothing proudly stands as a specialist in Schiffli embroidery, showcasing unparalleled expertise and mastery in this intricate art form. Our commitment to excellence is evident in our use of cutting-edge design and technology, which allows us to create exquisite and detailed patterns that set us apart in the industry. We invest in the best machinery and innovation to ensure that every piece we produce meets the highest standards of quality and beauty. At Pinnacle Clothing, we are dedicated to pushing the boundaries of what’s possible with Schiffli embroidery, delivering stunning results that combine tradition with modern sophistication.

At Pinnacle Clothing, our Laser Cut Embroidery technology pushes the boundaries of precision and creativity in garment design. This advanced technique allows us to create intricate patterns and sharp, clean edges that are difficult to achieve by hand. Using high-powered laser systems, we can cut and engrave fabric with exceptional accuracy, adding depth and dimension to each piece. The result is a flawless finish that enhances the aesthetic appeal of our garments, combining efficiency with artisanal quality. With Laser Cut Embroidery, Pinnacle Clothing continues to innovate, delivering refined, sophisticated designs that elevate modern fashion.

Pinnacle Clothing’s 3D Embroidery technology brings texture and depth to life, creating designs that literally stand out. This specialized technique layers threads to build raised, dimensional patterns that add a tactile richness to our garments. Combining advanced machinery with expert craftsmanship, our 3D embroidery not only enhances visual appeal but also elevates the sensory experience of each piece. Whether adding volume to logos, motifs, or intricate designs, Pinnacle’s 3D embroidery exemplifies our dedication to innovative artistry and quality.

Design

The Pinnacle Clothing design team is a diverse assembly of creative minds hailing from varied backgrounds in design and technology. Our designers, trained by esteemed professionals from top universities such as the Rhode Island School of Design and other prestigious institutions worldwide, bring unparalleled expertise to our brand. Rigorous training by UK designers and former buyers for renowned brands further enhances their skill set. From initial design sketches to the final product, every stage of our design process is meticulously handled in-house by garment experts. Our team includes specialists in fittings and silhouettes, 3D CAD designers, digital and analogue pattern developers, and innovators focused on sustainable fabrics. By consistently integrating the latest trends and maintaining environmental consciousness, we deliver premium collections at exceptional price points. We continuously explore new avenues of innovation across women’s, children’s, babies’, and men’s wear, ensuring our clients receive the best in modern fashion.

Innovation & Research (R&D)

At Pinnacle Clothing, we’re pioneering the fusion of tradition and technology through 3D CAD Draping, Design and CLO Tech. This advanced tool lets us visualize garments in a dynamic digital space, simulating fabric drape and movement with precision. By perfecting designs before production, we enhance accuracy, reduce waste, and elevate our commitment to sustainable, high-quality fashion solutions.

At Pinnacle Clothing, we’re working on introducing Virtual Reality (VR) and Augmented Reality (AR) into our garment manufacturing process. With AR, we can showcase intricate details and precise fit in a real-time digital space, giving designers and clients an interactive view of our creations before they are produced. VR further enhances this by immersing us in a fully 3D environment where fabrics, designs, and our hallmark Schiffli embroidery can be experienced virtually. This innovative approach empowers us to refine each piece meticulously, blending traditional craftsmanship with advanced technology to elevate quality, creativity, and efficiency in every garment. Drawing from her experience developing VR apps to aid Parkinson’s patients, Shreya Kumra is eager to lead her team in bringing this transformative technology to the garment industry.

Manufacturing

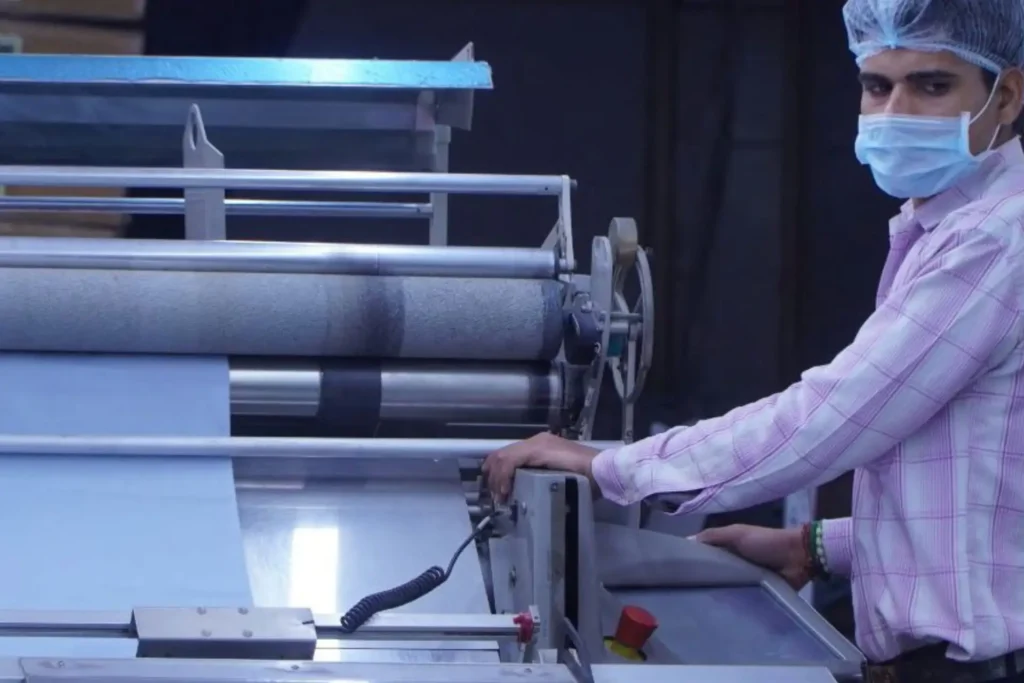

The Gerber Spreading System is a pivotal technology in Pinnacle’s garment manufacturing, streamlining fabric handling to boost efficiency and precision. By automating the fabric spreading process, it ensures layers are evenly laid without creases or tension inconsistencies, which enhances pattern accuracy and reduces material waste. This precision leads to more efficient fabric usage, supporting our sustainability goals while cutting costs. Additionally, the system reduces manual labor, promoting a safer work environment and allowing our team to focus on high-value tasks. Adaptable to different fabric types, the Gerber Spreading System empowers Pinnacle to maintain quality across all product lines, embodying our commitment to innovation and sustainability.

Equipped with approx 1,500 high-performance machines, including Juki single-needle UBT and Jack models, Pinnacle Clothing operates a cutting-edge sewing infrastructure. This setup allows us to produce up to 3 million pieces monthly, combining precision and efficiency to uphold our stringent quality standards in every garment.

At Pinnacle Clothing, we utilize hi-tech machinery to facilitate advanced finishing and washing processes. Our laundry division is equipped with automatic washers, extractors, PERK machines, and dryers, ensuring each garment receives the highest quality care. The combination of state-of-the-art equipment and expert craftsmanship guarantees that every piece retains its softness, durability, and perfect fit, meeting Pinnacle’s exacting standards before reaching our customers.

At Pinnacle Clothing, quality is our top priority, maintained through a stringent audit process at every stage of production. Our dedicated audit department conducts thorough inspections after stitching and finishing to ensure each garment meets our high standards. Before packing, every piece undergoes a final audit and is meticulously checked by our needle machines to guarantee precision and perfection. This rigorous quality control system ensures that only the finest products reach our customers, reflecting Pinnacle’s unwavering commitment to excellence and attention to detail.

At Pinnacle Clothing, our in-house laboratories conduct comprehensive performance testing and color approvals on raw materials, fabrics, garments, and trims at various production stages. Adhering to international standards sucH as well as specific buyer testing methods, our labs ensure the highest quality in every product. This rigorous process not only guarantees exceptional standards but also accelerates garment lead-time by enabling quicker quality approvals.

OUR HAPPY CLIENTS

What Client's Say?

Nulla metus metus ullamcorper vel tincidunt sed euismod nibh volutpat velit class aptent taciti sociosqu ad litora.

Alex Regelman

Co-founder, ColabrioNulla metus metus ullamcorper vel tincidunt sed euismod nibh volutpat velit class aptent taciti sociosqu ad litora.

Alex Regelman

Co-founder, ColabrioNulla metus metus ullamcorper vel tincidunt sed euismod nibh volutpat velit class aptent taciti sociosqu ad litora.

Alex Regelman

Co-founder, Colabrio

Project

Consulting

App